Services

Supervision of Installation

In order to ensure the supplied parts will last to the proposed lifetime, EGC supports its customers by supervising the installation, advise the proper procedure and tools for mounting and dismounting, specify the recommended fits of tolerances and test the parts after the installation.

Technical Training

EGC provides wide range of training courses and awareness sessions for engineering and technicians in order to give them the knowledge of rolling element bearings, designation system, clearances, mounting and dismounting, lubrication and monitoring tools.

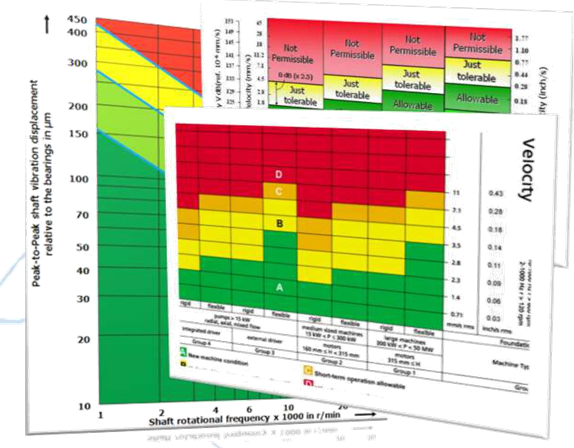

Vibration Analysis

Vibration analysis is the corner stone of successful reliability centered maintenance program. Routinely monitoring rotating equipment, we will be able to identify any fault and enable you to plan to take maintenance action before a failure occurs.

EGC do believe that the most important part of a successful program is to transfer the recommendations into action. The ultimate goal of the customer from a good reliability program is to have an action plan that results in improvement in the plant performance.

EGC team will be working with the concerned customer personnel to ensure the added value is realized.

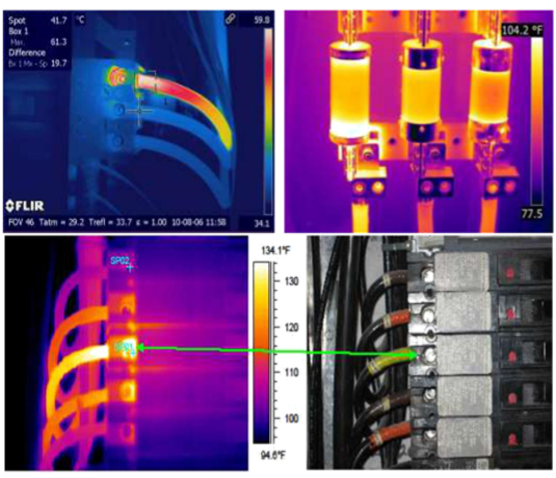

Infrared Thermography Imaging

Using infrared thermography, you can transform infrared measurements and construct radiometric images. Temperature is widely used in measurements and it can reliably indicate the condition of an object. Infrared imaging is particularly useful because you can inspect temperatures while the equipment is in its normal operating conditions.

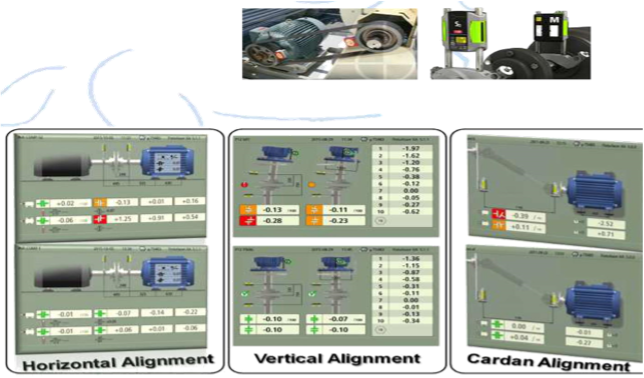

Laser Alignment

In rotating machinery, shaft misalignment exists when the centerlines of coupled shafts do not coincide. Recent statistics have proved that almost 50% of reported cases of failure in different components of machinery trains are originally caused by misalignment. These include bearings, seals, shafts and couplings failures.

Precise laser shafts alignment is used to reduce bearing and seal damage, vibrations, minimize energy losses, and reduce production downtime. EGC experienced team uses the latest technology instruments to perform wide diversity of laser shaft alignment techniques including:

- Horizontal shaft alignment.

- Vertical shaft alignment

- Cardan shaft alignment

- Pulleys laser alignment.

EGC team issues a technical report on the alignment job conducted including the estimated saving from energy losses by determining the drop in current consumption after the alignment.

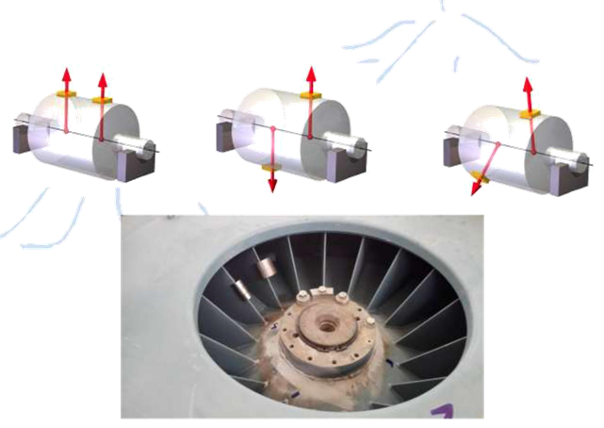

On-site Balancing

Mass unbalance is one of the most common causes of vibrations in rotating machinery. Balancing of rotors prevent excessive loading in bearings and avoid fatigue failures, which consequently increases the reliability of rotating machines. On-site balancing saves a huge effort, time and cost dismantling the rotor, sending it to be balanced on a balancing machine and reinstall it. EGC team has deep experience in on-site balancing in almost all industrial sectors.